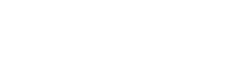

◆ Economical DX52D+AZ galvalume coil

Since the density of 55% Al-Zn is lower than that of Zn, the area of galvalume coil is more than 3% larger than that of galvanized steel sheet under the condition of the same weight and the same gold plating thickness.

Corrosion resistant

Zinc has active chemical properties. In the air at room temperature, a thin and dense alkaline zinc carbonate film is formed on the surface, which can prevent further oxidation, while aluminum can form an insoluble oxide layer in the air, which acts as a protective barrier.

Heat resistance

Galvalume coils can be used in high temperature environments up to 315 degrees.

Reflective

The galvalume coil has high reflectivity, and its heat reflectivity is almost twice that of galvanized steel. It is very suitable for steel structure metal roofs and can achieve energy-saving effects.

Easy to color

Galvalume coils have excellent adhesion to paint and can be painted without pretreatment and weathering.

◆ Standards

◆ Properties

Chemical properties of DX52D+AZ Galvalume Coil:

C: ≤0.12

Si: ≤0.50

Mn: ≤0.60

P: ≤0.10

S: ≤0.045

Ti: ≤0.30

Mechancal properties of DX52D+AZ Galvalume Coil:

Lower yield strength ReL/MPa: 140~300

Tensile strength Rm/MPa: 270~420

Elongation after break A80mm/%: ≥26

Plastic strain ratio r90 : -

Transverse Tensile Strain Hardening Exponent n90: -

Coating properties of DX52D+AZ Galvalume Coil:

Type of coating

| Density d/(g/cm3) | Coating form | Recommended Nominal Coating Weight/(g/m2) | Coating Code |

| type | code name |

| Al-Zn Alloy Coating | AZ

| 3.8

| Equal thickness plating

| 60 80 100 120 150 180 200 | 60 80 100 120 150 180 200 |

◆ Application

The AZ in the DX52D+AZ galvalume coil is an aluminum-zinc alloy coating. The mass fraction of aluminum in the molten aluminum-zinc alloy solution is about 55%, the mass fraction of silicon is about 1.6%, and the rest is zinc. The surface structure of the AZ coating is ordinary spangle, which is characterized by the aluminum-zinc crystal structure obtained by the normal condensation of the coating. The surface structure of the AZ coating usually has a metallic luster.

DX52D+AZ galvalume coil has excellent coating insulation protection and electrochemical protection, and is suitable for environments requiring high corrosion resistance. In addition, the DX52D+AZ galvalume coil has good high temperature resistance and heat reflectivity, and is widely used in roofs and walls. It can be used directly or as a substrate for color-coated panels.

Other applications of DX52D+AZ galvalume coil include:

Building and construction components (envelope systems, joists for residential buildings, roofs, walls, ceilings, doors);

Rainwater pipe fittings;

furniture and outdoor cabinets;

Unexposed auto parts;

Electrical appliances (oven, heater);

Pipes and computer cases, etc.

◆ Purchasing Information

|

Product name |

DX52D+AZ Galvalume Coil |

|

Surface |

light Oil, chromate, passivated, anti finger |

|

Thickness |

0.1-3.0mm |

|

Width |

600-1500 mm(Can be customized) |

|

Spangle |

Regular spangle,Minimum spangle, Zero spangle, Big spangle |

|

Coil Weight |

3 tons to 5 tons |

|

Shipping |

Standard packing for sea, air or rail transport |

|

Delivery |

10-15 working days after the receipt of 30% deposit |

|

Regular Order |

25 tons or one container,for less quantity,to contact with us for details |

|

Porductivity |

2000 tons per month |

*If you do not find what you are

looking for, please call us now. If you have found it, we are happy to

answer any questions or concerns you may have about stainless steel

grades and assist you through the purchasing process.

|

◆ Certificates

All of our products have been certified by Multiple quality certification and we conduct strict high quality control system.Manufacturer Test Certificate and the Third Party Inspection are all available.We have the worlds advanced processing machine to process any size as clientsrequirements.

◆ Our Advantages

Leave a Comment